The base metal hardly melts.

We use silver solder and the processing temperature is between 700℃ and 800℃. Because it is not comparatively high temperature, it will not do harm to the base metal during the brazing process.

Beacuse the solder can flow in narrow spaces of the base metals by wetting, brazing has the ability to join the metals which have many places to be joined or in complex shapes easily.

※We have 5 High Frequency Induction Heating Equipments. It is different from Flame brazing because you can check with your eyes during the brazing process.

※We have 5 High Frequency Induction Heating Equipments. It is different from Flame brazing because you can check with your eyes during the brazing process.

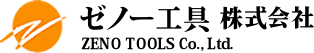

The Plasma arc is formed between the electrode and the work piece. Then the metallic powder and the carrier gas are put in together to start welding.

Because of the high heat concentration, it has a higher welding speed and the bead width is narrow.

There is no sputter.

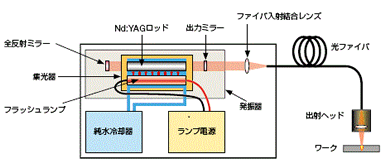

※We develop the PTA welding equipment used to overlay the rotary cutter of the pelletizer with the stellite independently. And we have been doing high-quality welding sustainably for a long time.

※We develop the PTA welding equipment used to overlay the rotary cutter of the pelletizer with the stellite independently. And we have been doing high-quality welding sustainably for a long time.

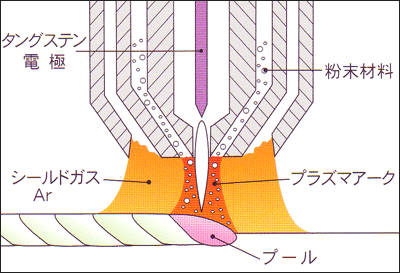

Let a strong flash of light irradiate the meterial which generates the laser beam called YAG(Yttrium Aluminium Garnet) rod, and widen the laser beam coming from media, then produce laser beam with the energy which can be used for material processing.

Because its emission wavelength is only 1.06μm, it can be transmitted by silica fiber.

It has high power density that the metals can be melted immediately. It also radiates heat very slowly allowing for narrow deep welds and small-attected zones(Less distortion and hurnt).

※We have a YAG laser welding machine, besides nomal repairing, we are studying how it can be used to repair the blade points of stellite rotary cutter.